5 Tricks That Make Working with Flexible MDF Easy

MDF sheets are quite popular in construction. They are affordable, reliable indoors, and highly versatile due to their good workability. Read on to discover five tricks that make it easy to work with flexible MDF.

Why Choose Flexible MDF?

Here are reasons to consider using flexible MDF sheets on your indoor projects:

- MDF does not splinter when cut. As long as your saw blade is sharp, your rips and crosscuts will be smooth, clean and razor-sharp.

- Routing MDF produces remarkable results. Using a router gives MDF edges a smooth texture, which you can sand into a higher-quality finish.

- MDF is stable. It does not warp or swell with humidity and temperature change and maintains its flat appearance 100% of the time. You can’t go wrong with choosing MDF for projects that require a flat surface.

- It does not dent easily. Your MDF furniture will not dent or crack with everyday use or occasional abuse.

5 Tricks That Make Working with MDF Easy

1. Reinforce Your Flexible MDF for Added Strength

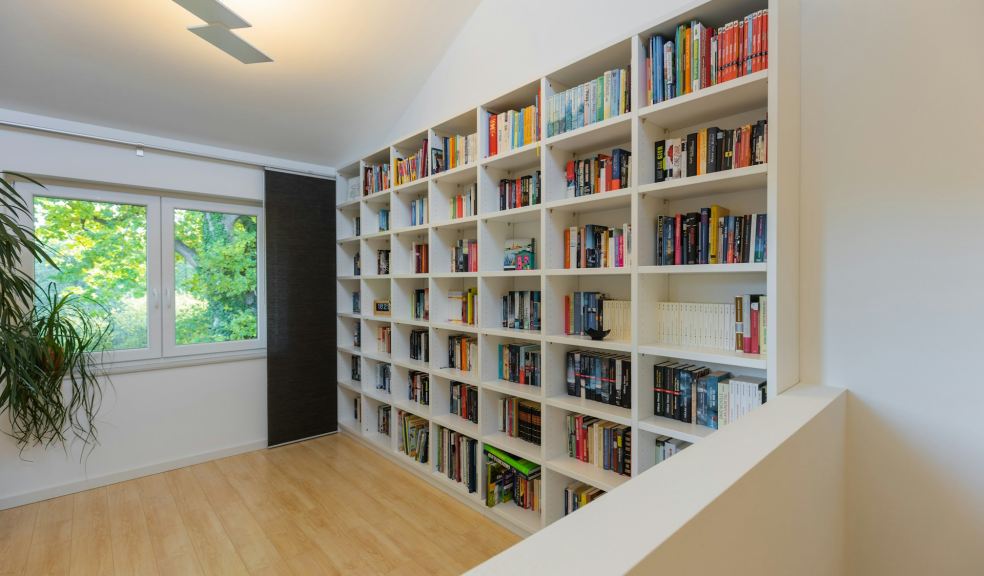

Strengthen your flexible MDF structures by adding vertical supports every 25–28 inches. The added reinforcement increases their load-carrying capacity and allows them to hold items without sagging.

You can adjust the spacing between the supports depending on the purpose of the structure you’re making. Keep the supports close together if you intend to store heavy items on the shelves or cabinets. Space them out if you want to use the cabinets to store lightweight items. But overall, use your judgement to decide what a good spacing is.

2. Stack Flexible MDF Sheets for Extra Rigidity

Stack and glue several MDF sheets to double the material’s strength. This hack works great for projects requiring extra strong materials, such as tabletops. The combined density of all layers forms a strong and rigid surface that can serve different purposes.

3. Improve Flexible MDF Edges with Laminate and Screen Trim

MDF edges have a grainy look. This shouldn’t stop you from using MDF or your built-ins and cabinets. Cover the edges using laminate or screen moulding to improve the aesthetic of any furniture you make using MDF.

4. Prep Your MDF Surfaces for Paintwork

Before painting your flexible MDF sheets, take some time to prep the surface. The grainy texture on the edges, especially, needs to be smoothed and the edges sealed. Otherwise, the paint won’t stick to it well.

- Begin by cleaning the MDF surface.

- Use a gentle cleaner and then wipe it off with a soft cloth.

- Apply primer to the MDF. Choose a primer formulated for MDF. Use a foam roller to spread the primer evenly on the front and back and a small brush for the edges. Wait for the primer to dry.

- Next, sand the surface. A super-fine grit, like 600-grit sandpaper, will give you a smooth finish.

- Apply a second coat of primer and let it dry.

- Sand the surface.

- Apply the first paint coat. Let it dry, then apply a second coat.

- Seal the paint with a coat of finish.

5. Best Way to Use Fasteners on Flexible MDF

You can use staples on MDF joints. Staple no more than 25 mm from the edge and control the air pressure so the staples do not deeply penetrate the sheet.

If using nails, choose a slim gauge, preferably no higher than 13 or 14 gauge. Helical and annular groove nails

Drilling screws into flexible MDF can be challenging for two reasons:

- It’s hard for the screw to push through the dense wood fibres that make up the MDF

- Once you push in the screw, it splits the sheet, but the loose wood fibres cannot support the screw because they are not strong and compact.

However, there’s a workaround that can help your screws stay in place:

- Use MDF screws

- Use a pilot hole to minimise splitting.

- The pilot hole should be 2-3 mm deeper than the screw insertion.

- Add a few drops of glue to hold the screw in place.

- Drill the screw into place.

- Do not overtighten the screw.

Conclusion

MDF sheets are suitable for various indoor applications, including flooring, furniture, cabinetry, shelving, wainscoting and other decorative panelling. amplify

For a great selection of flexible MDF and other sheet materials, Sheet Materials Wholesale offers one of the UK’s most trusted online catalogues — ideal for both trade professionals and DIY projects.

FAQs

- How long does flexible MDF last?

The durability of any MDF product depends on its build quality. High-quality MDF sheets and boards last up to 10 years. You can extend the durability of your MDF products by keeping them moisture-free. Do not use MDF outdoors, in bathrooms, kitchens or other high-moisture zones where it will be constantly exposed to water. Water wears out MDF fast, so only use the material in dry places.

- Should I apply a top coat after painting my flexible MDF sheet?

You do not have to add a top coat when painting MDF. However, a top coat will seal the paint so it lasts longer. It will also preserve the vividness of the colour and prevent fading. Without a top coat, the paint will deteriorate fast due to reactions with moisture and oxygen. Applying a protective finish on top ensures the paint doesn’t scratch or peel off easily. This is important if the MDF piece is used in a high-traffic area where it’s likely to be mishandled. Plus, it makes cleaning the painted surface easy.